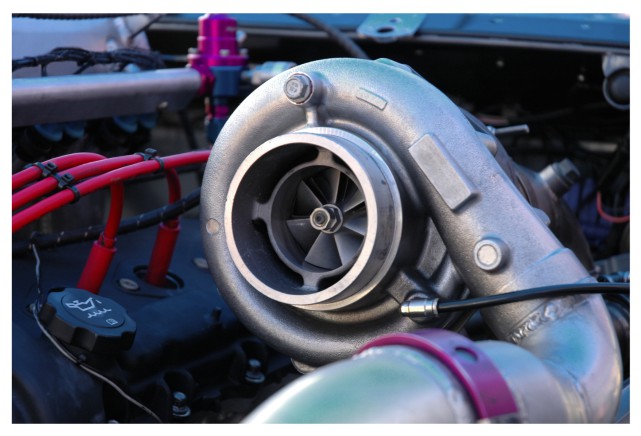

Turbocharger deposits are caused by hot shutdowns. The temperature of the turbocharger itself can also get very high, especially in the turbine and compressor wheels and the bearing housing. These components can reach up to 500 degrees Celsius (932 degrees Fahrenheit) or more in some cases. When an engine is run hard and shut off without idling before shutdown the oil and coolant flow is also shut off to the turbocharger. Oil is the life blood of the turbocharger bearing system. The bearing system relies on a super thin film of oil that supports the turbine and compressor wheels as they rotate up to 80,000 to 200,000+ rpm. Since the turbocharger turbine and compressor wheels are still spinning after shut down the remaining oil is the only source of lubrication available because the engine is not running. The oil with this extreme heat and no flow can become cooked in the bearing housing and clog up the turbine end oil feed like cholesterol in your arteries and starve the bearings of lubricating oil. This eventually leads to turbocharger failure. On top of that no coolant flow means longer cool down time, which causes the oil to cook even more! This results in oil sludge or coke buildup.

Oil has to flow into and drain out of a turbocharger for proper lubrication – turbo damage leading to failure is caused when the oil feed line or drain line becomes restricted by deposits!

Problem: Poor quality conventional and synthetic blend oils can be the root cause of deposit build-up and sludge formation.

Solution: A high-quality 100% synthetic oil will have greater oxidation resistance and a higher amount of detergents and dispersants that will help prevent deposits and sludge from forming because it’s always cleaning and preventing contaminants from adhering to parts while neutralizing acids. AMSOIL synthetic lubricants are formulated with base oils that have a saturated molecular structure, meaning oxygen is prevented from attaching. This provides inherent heat and oxidation stability over conventional oils that are unsaturated. Because AMSOIL synthetic oils do not contain contaminants like conventional mineral oils, their base composition does not accelerate oxidation. AMSOIL synthetic lubricants contain oxidation inhibitors that are far better than conventional oils. Oxidation inhibitors are sacrificial in nature, meaning they deplete, and are used over time. Since AMSOIL base oils have better oxidation stability on their own, oxidation inhibitors in AMSOIL synthetic oils last longer because they are not depleted as rapidly. AMSOIL uses a combination of oxidation-inhibitor systems for different temperatures and application needs.

6 tips on how you can reduce turbocharger deposits and maximize the life of your turbocharger

- After a hard drive DO NOT shut off engine right away

- Allow the engine to idle for 30 to 60 seconds before shutting off engine so the hot side of the turbocharger can cool down and the turbine wheel slows down in RPM

- It is extremely important to allow the turbine/compressor wheel to reduce its speed after a hard drive because if you don’t follow these steps the turbo will still be spinning at thousands of RPM’s after shutting off the engine without coolant or oil flow!

- The main purpose is to allow the turbocharger to reduce its rotating speed while coolant and oil is still flowing through the turbocharger since the engine is running at idle – the exhaust temperatures will reduce at idle as well

- NEVER rev your engine before shutting off engine!

- Use high quality 100% Synthetic Motor Oil

In Conclusion

Following these steps will greatly extend the life of your turbocharger wether you have a daily driver or racing vehicle or a daily driven racing vehicle! Our advice comes from personal experience and industry knowledge.

Check out our other blog posts and learn more about the amazing benefits of using AMSOIL!