Pour Point Test Method

While certain regions may never have to contend with extremely cold temperatures, it should be noted that lubricants with lower pour points may also aid in increased fuel economy, energy efficiency, and ease of starting. The most common method for determining the pour point of oil is the Standard Pour Point Test (ASTM D97). In this test, an apparatus cools an oil sample to determine its pour point. A vial is filled with a specific amount of test oil and then placed into the bath to cool. After every 5 ° F drop in temperature, the vial is removed and tilted. If the oil moves (flows) off of a specified fill line within five seconds, it is cooled another 5 ° F. The test temperature continues to decrease until no flow occurs within the five-second tilting periods, or until -76 ° F (-60 ° C) is reached (the lowest testing limit of the cooling bath). This temperature is then recorded and + 5 ° F is added. This new temperature is reported as the oil’s pour point.

OilBuddy’s Take

In other words, a lubricant that can be poured at low temperatures also provides fuel efficiency benefits to automobiles. The low viscosity of these lubricants reduces drag on engine components, allowing them to move more efficiently.

AMSOIL Advantage

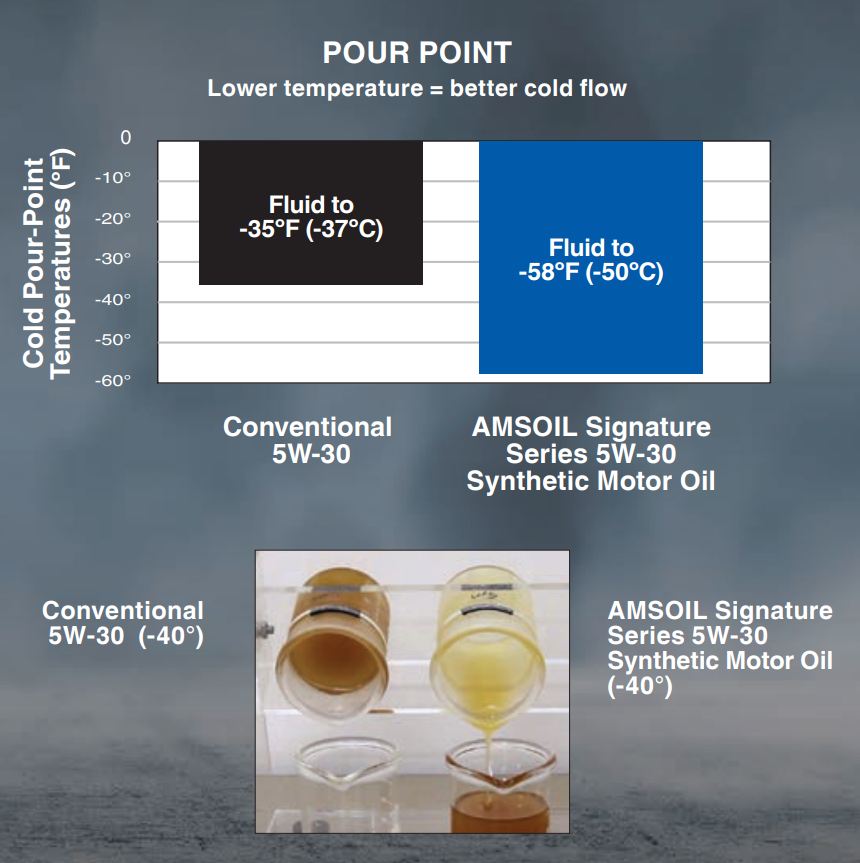

AMSOIL Advantage Superior Pour Point AMSOIL synthetic lubricants have inherently low pour points. Such cold temperature performance allows the oil to circulate in a lubrication system easily at frigid temperatures. Being able to circulate at such temperatures means that engine components are protected during cold starts; Typical mineral oils exhibit a delay in their ability to circulate and expose components to metal-to-metal contact, increasing wear and reducing engine life.

Useful Links

SHOP NOW AT AMSOIL BY EQUIPMENT TYPE