NOACK VOLATILITY TEST (ASTM D5800)

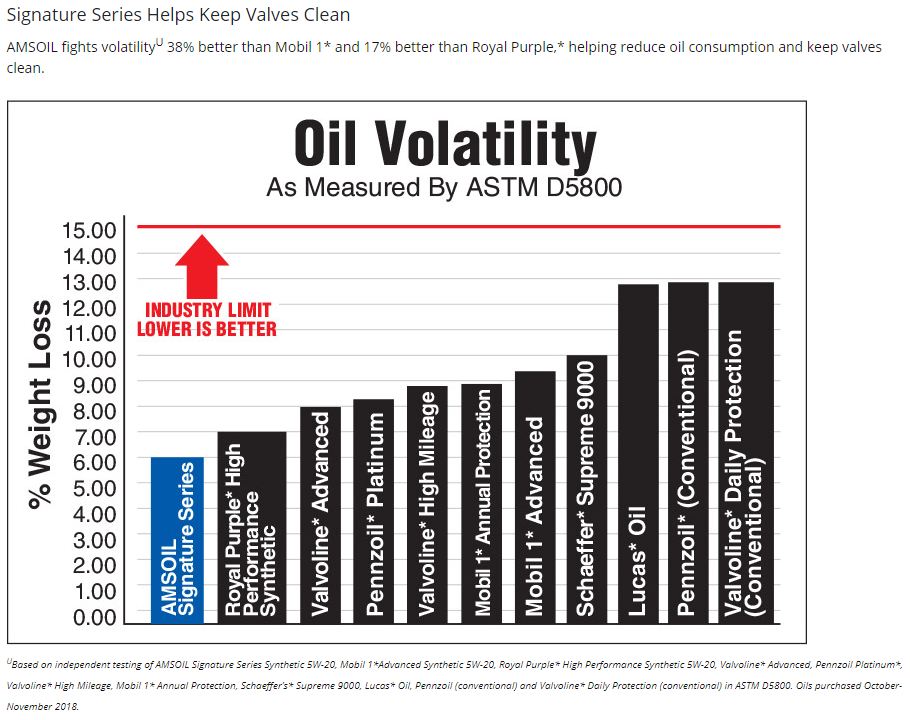

Simply put, lower oil volatility offers reduced oil burn-off and keeps valves clean. When comparing motor oils the industry maximum limit is 15%. When choosing an oil, the lower the Volatility percentage is better.

NOACK VOLATILITY TEST (ASTM D5800) The most common method used in measuring oil volatility is the NOACK Volatility Test. In this test, an oil sample is weighed and then heated to a temperature of 482° F (250 ° C) for one hour. During this time, dry air is passed over the sample, which carries off the oil vapors that have boiled off and deposits them in a beaker attached to the apparatus. Finally, the original sample is removed and re-weighed. Any reduction in weight is reported as a percentage loss of the original weight. The entire procedure is very similar to the operation of a petroleum fractioning tower or still. Currently, API SN and ILSAC GF-5 performance classifications require weight lost due to volatility to be no greater than 15 percent for viscosity grades of motor oil.

AMSOIL Advantage re: NOACK VOLATILITY TEST (ASTM D5800)

AMSOIL Advantage Less Volatility AMSOIL synthetic lubricants are engineered to have uniform molecular shapes and weights. The advantage to this homogeneous composition Is that there are fewer ‘light fractions’ that are susceptible to evaporation. AMSOIL synthetic lubricants are more stable than conventional motor oils for improved resistance to burn-off. Signature Series Helps Keep Valves Clean -AMSOIL fights volatilityU 38% better than Mobil 1* and 17% better than Royal Purple,* helping reduce oil consumption and keep valves clean.

The Importance of Noack Volatility %

Low volatility % also reduces engine oil consumption and reduces the amount of “crankcase oil vapour” that gets drawn into the intake via engine vacuum from the PCV system. This reduces or eliminates oil residue coating the inside of your intercooler, throttle body, intake manifold and on the intake valves. This also helps to maintain the perfect air to fuel mixture in your cylinders because you eliminate having to burn “crankcase oil vapours” which in turn maximizes your power output. Oil vapour reduces your octane rating because it has to burn with the fuel that was injected. As you know oil is harder to burn so it’s mixed with fuel for emission reasons, that oil is not as combustible as fuel so it has the potential to ignite when it was not supposed to. Pre-ignition or “detonation” is when the air/fuel mixture in the cylinder ignites before the spark plug fires. PCV Oil vapour reduces efficiency and causes increased emissions since oil vapour is hard to ignite it burns dirty. Less oil vapour being burned means that the catalytic converter substrate also benefits from not getting poisoned. Catalyst poisoning occurs when the catalytic converter is exposed to exhaust containing substances that coat the working surfaces, so that they cannot contact and react with the exhaust. Reduced emissions output is important for a vehicles emission system, the vehicle manufacture and the environment!

Useful Links

SHOP NOW AT AMSOIL BY EQUIPMENT TYPE