AMSOIL Advantage

Frictional Properties and Anti-Shudder Performance

AMSOIL transmission fluid is fully fortified with friction modifiers engineered to deliver outstanding clutch-holding capacity, torque-transfer and anti-shudder performance over the life of the fluid.

The coefficient of friction (how two surfaces behave relative to their movement against one another) is a major factor in shift quality, and fluids can be formulated to exhibit ‘grabby’ or ‘slippery’ characteristics, determined by the friction modifiers used in the formulation.

Different transmission materials require different frictional properties. If friction modifiers break down in the fluid, shift quality will become hard and erratic. AMSOIL fluids resist friction modifier breakdown by using high-quality base oils in tandem with robust friction modifiers. Their ability to maintain precise friction performance over the life of the fluid allows clutches to operate smoothly with no harsh or erratic shifting.

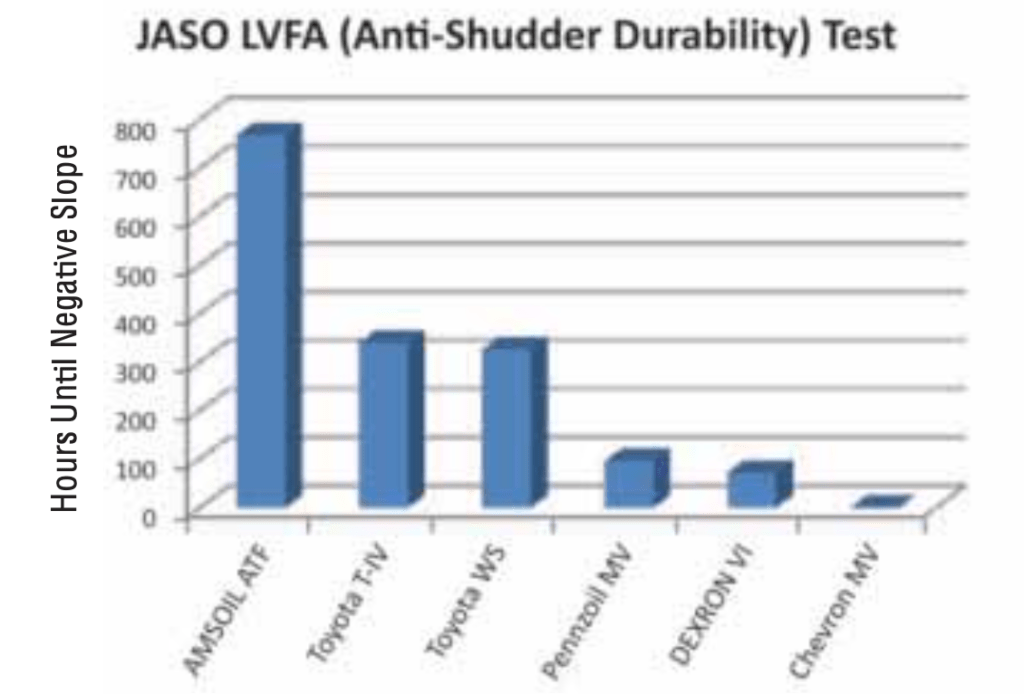

THE JASO LVFA/ANTI-SHUDDER DURABILITY TEST

The Japanese Automotive Standards Organization (JASO) requires a Low Viscosity Friction Durability (LVFD) or Anti-Shudder Durability (ASD) test to qualify transmission fluids for use in sensitive Asian transmissions such as those in Toyota and Nissan applications.

AMSOIL Advantage

The results of the JASO LVFA test determine the duration for which transmission fluids maintain the positive friction-to- speed relationship that reduces torque converter clutch shudder.

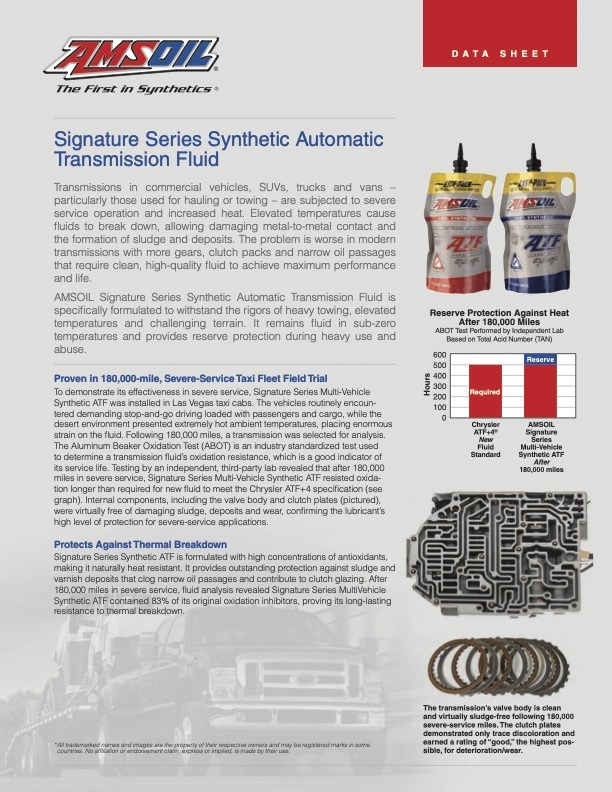

Heat/Oxidation Resistance

All lubricants oxidize when exposed to increasing temperature; the higher the temperature the faster the oxidation rate. Oxidized oil thickens and loses lubricity, requiring more energy and increasing overall fuel consumption. Oxidized oil will also produce harmful acids that can lead to corrosion and the formation of sludge and varnish.

AMSOIL base oils are engineered with fully saturated synthetic molecules, which makes them naturally resistant to oxidation. Fully saturated molecules have a sealed molecular structure with few openings for other molecules, such as oxygen molecules, to attach. The fully saturated structure of AMSOIL fluids resists thickening from thermal and oxidation reactions. In addition to their natural oxidation resistance, AMSOIL lubricants are fortified with antioxidants that help further extend fluid life.

Powerful dispersants in AMSOIL automatic transmission fluids prevent sludge and varnish deposits from agglomerating into larger, damaging particles that clog valve body passages and can harm the transmission and cause failure.

AMSOIL automatic transmission fluids have exceptional high-temperature performance and oxidation resistance, providing significantly increased fluid life expectancy over conventional transmission fluids

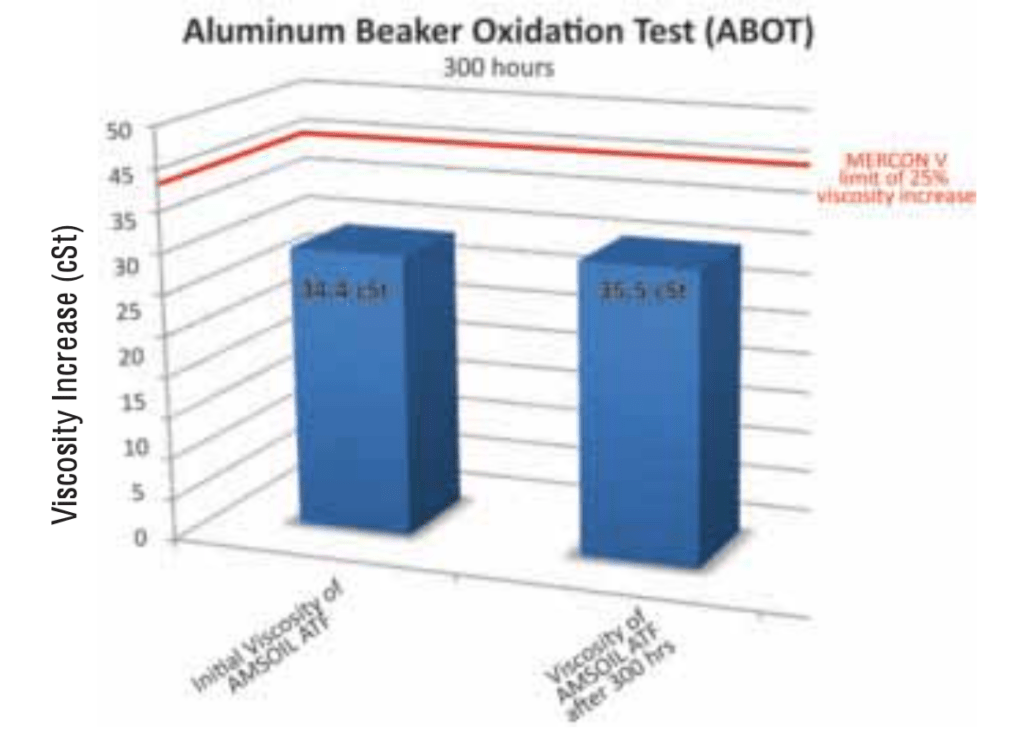

THE ALUMINUM BEAKER OXIDATION TEST (ABOT)

The MERCON V Aluminum Beaker Oxidation Test (ABOT) is a 300-hour oxidation test in which a gear pump circulates and shears the test fluid in an aluminum beaker. Fluid temperature is maintained at 311°F (155°C), and samples are drawn and analyzed at intervals throughout the test. To evaluate the fluid’s tendency to attack metal materials, metal catalysts commonly found in transmission systems are also submerged in the test fluid. Figure 4.8 shows how AMSOIL Multi-Vehicle ATF stands up to the MERCON V viscosity-increase specifications.

In order for a fluid to pass the current MERCON V specifications, it must not exceed a 25 percent viscosity increase following the 300 hour test. AMSOIL Multi-Vehicle ATF has an initial 34.4 cSt viscosity. In order to pass the MERCON V specification, it can’t exceed 43 cSt upon completion of the 300-hour oxidation test.

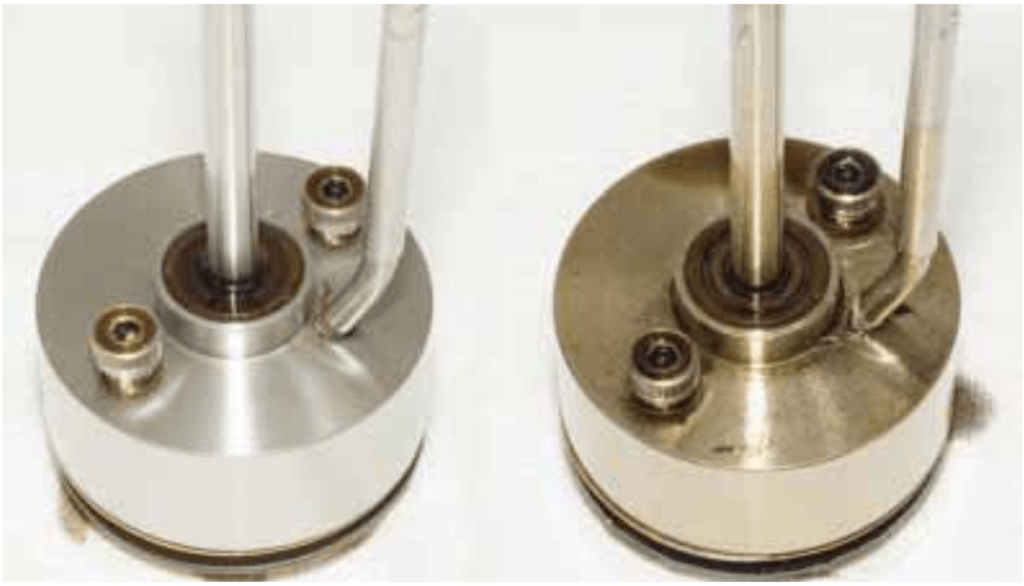

Sludge and varnish develop when oxidized by-products from the oil agglomerate. The absence of sludge and varnish formation during the 300-hour ABOT Test, shown in Figure 4.9, demonstrate AMSOIL Multi- Vehicle ATF was able to inhibit oxidation reactions, maintaining its ability to provide clean and efficient transmission operation.

AMSOIL Advantage

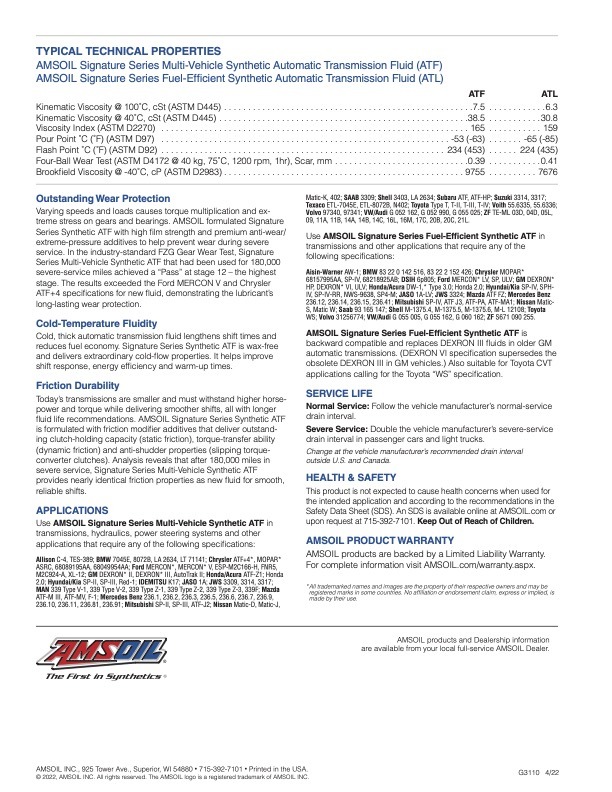

Shear Stability and Wear Protection

The uniform molecular structure of AMSOIL synthetic automatic transmission fluids contributes to their outstanding film strength and shear performance and allows them to maintain a protective fluid barrier during aggressive operation. While poor-performing, conventional fluids rupture under the pressure, AMSOIL automatic transmission fluids are fortified with anti-wear and extreme-pressure additives that provide a sacrificial layer of protection.

Conventional oils do not have the advantage of a uniform molecular structure and lose viscosity under normal conditions. Synthetics have inherent molecular strength and provide superior protection against shear forces.

GEAR DURABILITY TEST

The Gear Durability Test determines a transmission fluid’s ability to prevent planetary gear wear under conditions of high temperature and high load. The test simulates conditions of severe uphill driving, towing, extreme high temperatures and high torque.

It is completed in two rigorous phases on a major OEM four-speed automatic transmission. The first phase subjects the transmission to constant running speeds in second gear under high-torque conditions. The second phase subjects the same transmission to a constant speed while doubling the amount of torque from the first phase.

At the conclusion of the test, the transmission is disasembled and the planetary gear set is examined. Successful fluids support the transmission for the entire duration of the test with minimal tooth pitting and gear fracture.

AMSOIL Advantage

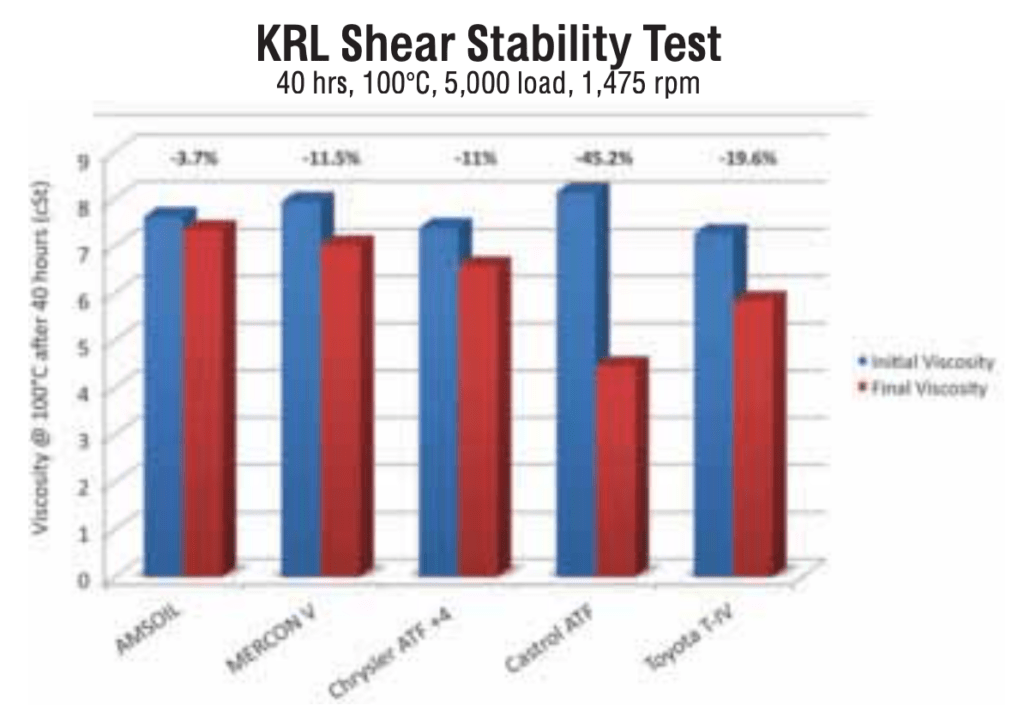

KRL SHEAR STABILITY TEST

A gear lubricant’s shear stability is measured by the KRL Shear Stability Test. This mandatory test qualifies gear oils under the SAE J-306 standard. In the KRL Shear Stability Test, fluid is tested at 212°F (100°C) with a tapered-roller bearing under a 5,000 lb. load, spinning at 1,475 rpm. After 40 hours of rigorous testing, fluid viscosity loss is measured.

Cold-Temperature Properties

Cold temperatures increase the viscosity of transmission fluid, which can result in fuel economy loss. Transmission operation can also suffer, from sluggish response to reduced shifting capacity.

AMSOIL Multi-Vehicle ATF provides outstanding cold-temperature performance and provides fluidity down to -53°F (-47°C). The wax-free, uniform molecular structure of AMSOIL synthetic automatic transmission fluids provides responsive shift times and improved fuel efficiency in cold temperatures.

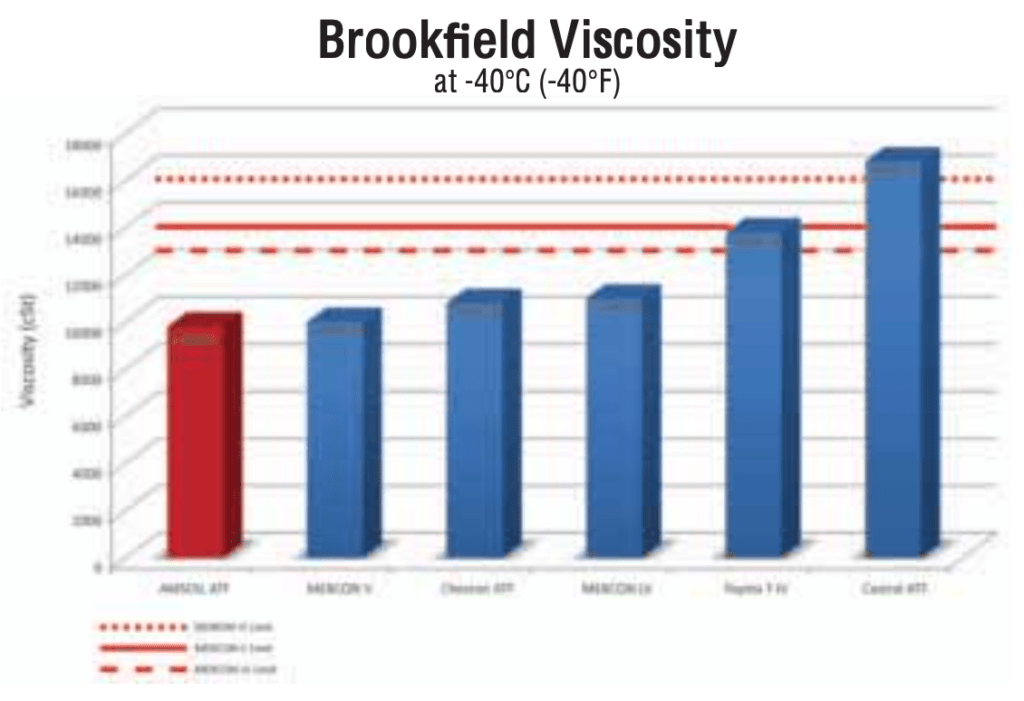

AMSOIL Multi-Vehicle ATF exceeds the cold-temperature performance benchmarks with a viscosity of 1,295 CP at -4°F (-20°C) and 9,800 CP at -40°F (-40°C), significantly below the maximum limit for MERCON V fluids, which are 1,500 cP and 13,000 CP respectively.

AMSOIL Multi-Vehicle ATF helps eliminate viscometric drag during extreme cold temperatures, which improves mechanical efficiency, fuel economy and wear protection.

AMSOIL Advantage

AMSOIL ATF provides outstanding cold-temperature performance compared to major OEM transmission fluids and service brands. It resists excessive thickening at -40°F (-40°C), significantly better than the fluids compared in Figure 4.12. Note that Castrol ATF exceeds the limits for all three fluids.

Foaming

The gears, bearings and clutches in automatic transmissions churn oil and air together during operation, which can cause foam development.

Foam harms the operation and longevity of transmission components because it can significantly reduce critical fluid-film barriers. Foam in transmission oil can cause erratic shifting and starve the transmission of fluid, both of which can cause transmission damage or failure.

AMSOIL ATF is formulated with anti-foam additives designed to rapidly reduce the surface tension of foam bubbles that develop. These additives ensure that foam rapidly collapses, minimizing the risk of entrained air and maintaining a protective fluid barrier between components.

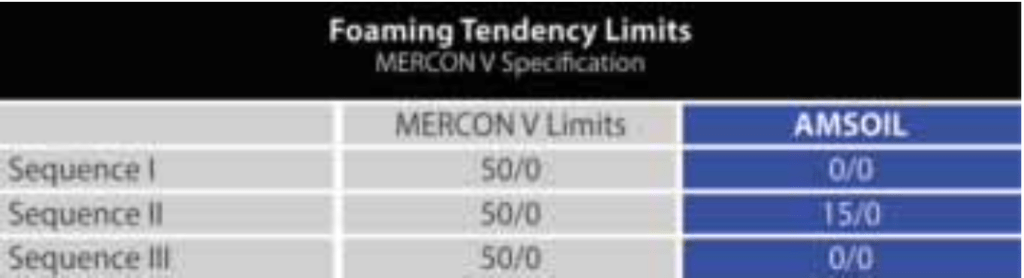

FOAMING TENDENCY TESTING (ASTM D-892)

The Foaming Tendency Test (ASTM D-892) evaluates a lubricating fluid’s tendency to foam. Air is blown through the test fluid at å specific temperature, and the volume of foam that remains after a 10-minute settling period is measured. The test is conducted in a number of sequences to simulate the start-stop operating conditions common for automatic transmission fluids.