Amsoil Performance Improver – Best Fuel Injector Cleaner 2023

The best fuel injector cleaner that actually works, is AMSOIL P.i. Performance Improver Fuel Injector Cleaner Gasoline Additive.

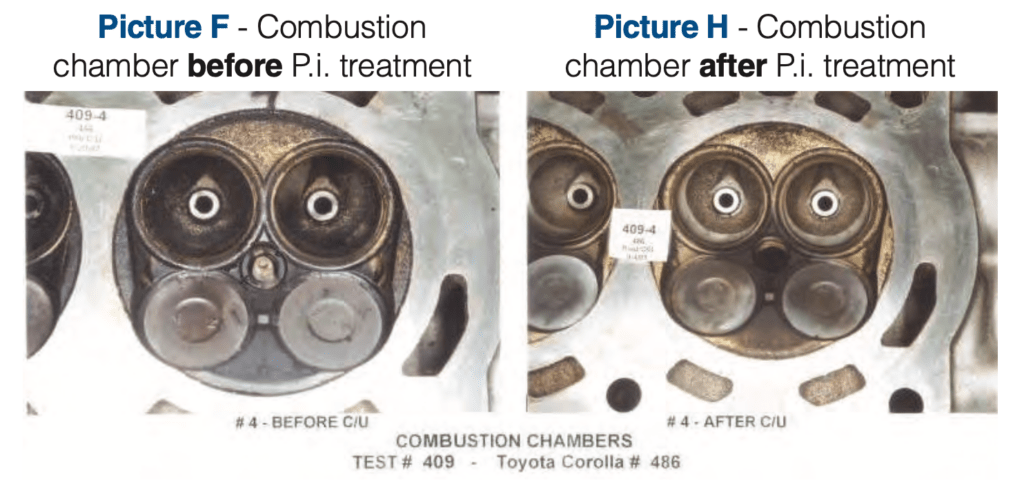

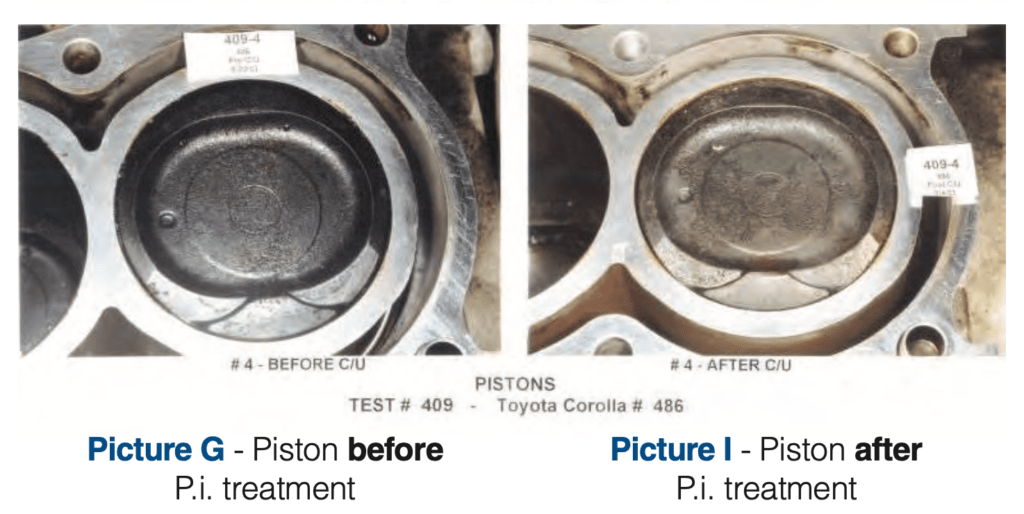

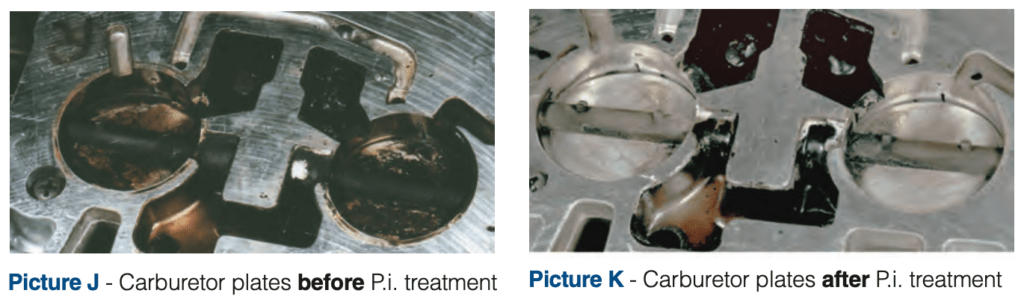

Learn More and See the Before and After Pictures below of this excellent fuel injector cleaner for both gasoline direct-injected (GDI), port fuel injected engines, and carbureted engines.

Does fuel injector cleaner work?

Yes! Whether deposits have built up over a relatively low number of miles, or they have accumulated over 100,000 miles, P.i. fuel injector cleaner effectively removes them. Because fuel injector deposits and the associated performance issues usually build up slowly over time, motorists often attribute the decreased performance to the increased age of the vehicle.

When the deposits are removed in only one tank of gasoline, the performance improvement is immediate and significant.

AMSOIL P.i. fuel injector cleaner is a potent, deep-cleaning gasoline performance improver featuring concentrated detergents that aggressively clean stubborn, power-robbing deposits from injectors, valves, and combustion chambers. P.i. Fuel Injector Cleaner cleans your entire fuel system and restores up to 14% horsepower1 in one tank of gasoline. The P.i. fuel injector cleaner bottle is fully compatible with the cap-less fuel systems of modern vehicles for easy fuel injector cleaner application.

What does fuel injector cleaner do?

AMSOIL P.i. Fuel Injector Cleaner Treatment Does The following in one tank of gasoline.

- Maximum Deposit Clean-up

- Removes Fuel Injector Deposits – restored GDI fuel injectors to a 100 percent flow rate after one tank of fuel during fuel injector cleaner testing.

- Restores up to 14% horsepower1

- Improves fuel economy

- Fights Intake Valve Deposits

- Cleans Combustion Chamber Deposits

- Reduces need for costly higher-octane fuel

- Reduces noise from carbon rap and pre-ignition

- Controls pre-ignition “knock”

- For use in gasoline powered cars and trucks

- Capless-Compatible Packaging

- Safe for use with catalytic converters, oxygen sensors, oxygenated gas and up to 15% ethanol blended gas.

- P.i. fuel injector cleaner helps pass emission tests (treat one full tank of gas, run that tank and fill up again prior to test).

- AMSOIL PRODUCT WARRANTY

1Based on third-party testing in a 2016 Chevrolet* Silverado* 1500, 5.3L V-8 GDI with 100,616 miles, using one tank treated with AMSOIL P.i. Fuel Injector Cleaner Actual results may vary.

Maximum Deposit Clean-up

AMSOIL P.i. fuel injector cleaner features aggressive additives that attack the most common forms of engine deposits and limit their effects.

AMSOIL P.i Fuel Injector Cleaner Removes Fuel Injector Deposits

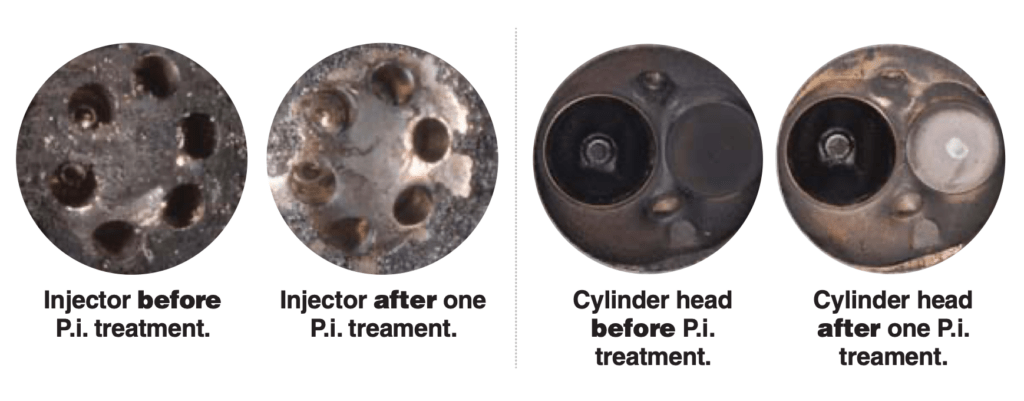

Most new engines feature gasoline direct injection (GDI) to boost power and improve fuel economy. These injectors are located inside the intense heat and pressure environment of the combustion chamber, making them particularly vulnerable to deposits. Extreme pressure combined with incomplete fuel combustion can lead to dramatically increased soot (particulate matter) levels. Direct injection typically creates 30 to 40 times more soot than port fuel injectors (PFI). Even a minimal amount of injector fouling can lead to increased pollution and wear and decreased power and fuel economy.

The Problem – Injector deposits:

• Decrease efficiency, power, and fuel economy

• Increase exhaust emissions

• Contribute to poor starting and rough idle

The Solution:

AMSOIL P.i. fuel injector cleaner removes stubborn deposits and keeps injectors functioning as they should.

Testing shows P.i. fuel injector cleaner restored GDI fuel injectors to a 100 percent flow rate after one tank of fuel.

Restores Horsepower

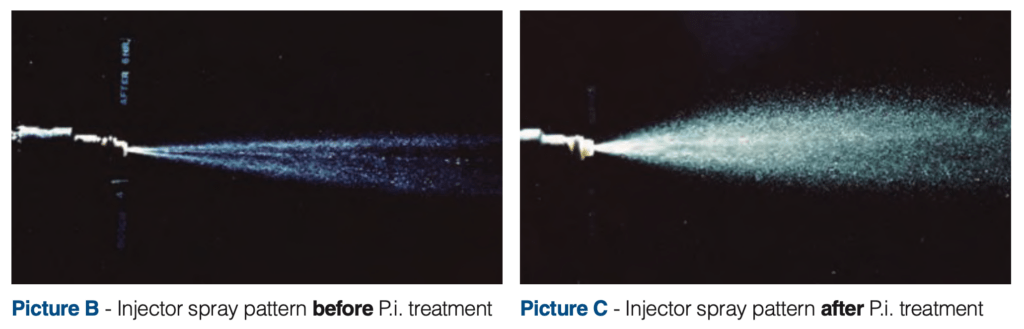

We set out to once again demonstrate the superior performance of P.i. fuel injector cleaner through third-party testing using a purchased 2016 Chevrolet Silverado with 100,616 miles on the odometer. Prior to testing, the truck was run on a chassis dyno and measured for HP. The 5.3L GDI engine was then disassembled, photographed, and reassembled. Following a single tank of fuel treated with P.i. fuel injector cleaner driving at highway speeds, the truck was again strapped to the dyno. It measured an incredible 14% improvement in horsepower. The engine was then disassembled once again to see the impact P.i. fuel injector cleaner had on deposits.

The images below demonstrate the powerful cleaning performance of AMSOIL P.i. fuel injector cleaner on injectors and cylinder heads to significantly restore power and efficiency.

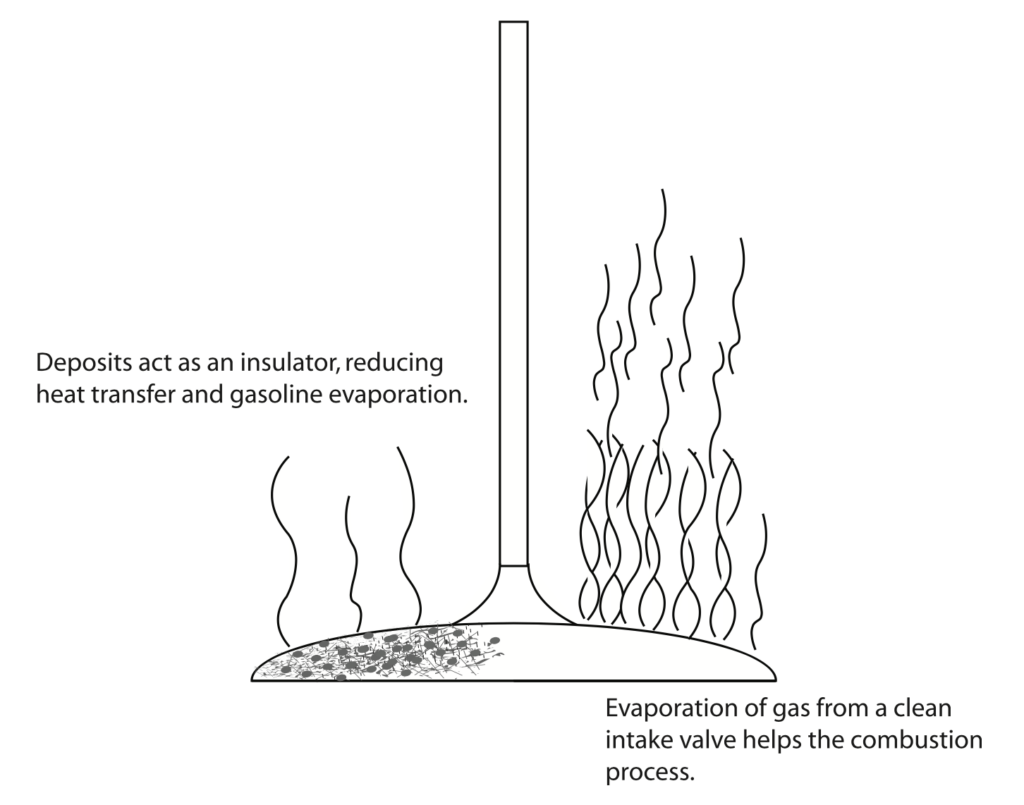

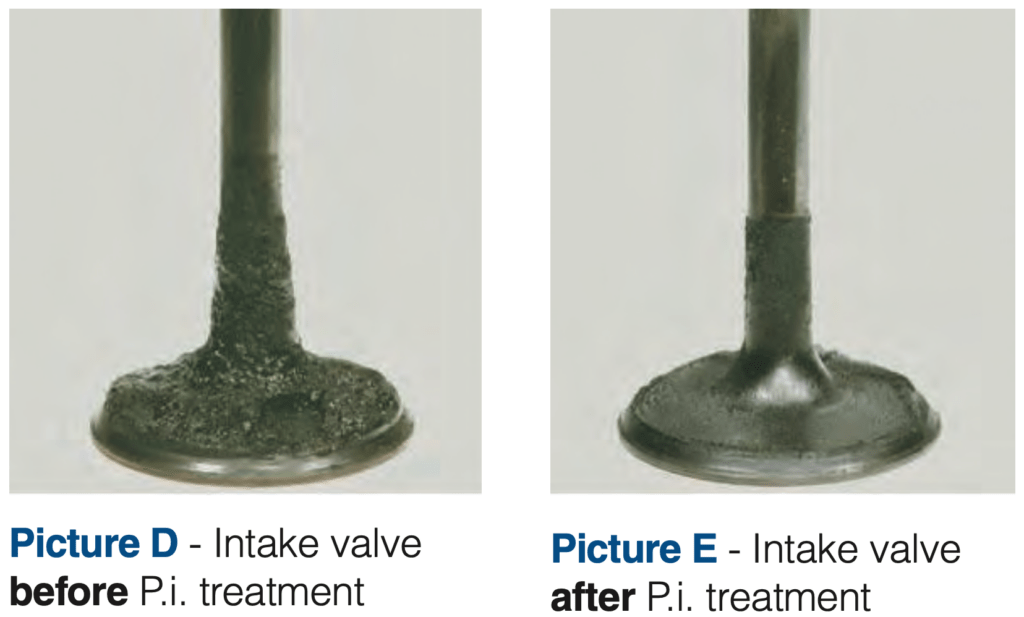

Fights Intake Valve Deposits

Valve deposits alter or restrict airflow patterns in the cylinder. They disrupt the balanced air/fuel ratio by momentarily absorbing and releasing fuel. The deposits can also cause valve sticking by getting in the way of the valve stem and guide.

The Problem – Intake valve deposits:

• Decrease power and efficiency

• Increase exhaust emissions

• Lead to potential valve failure

The Solution:

AMSOIL P.i. fuel injector cleaner helps keep valves clean and moving freely

Cleans Combustion Chamber Deposits

Combustion chamber deposits increase compression and absorb heat during combustion. Later, they release that heat during the intake cycle. In some engines, deposits can cause the piston to actually hit the cylinder head – a process known as “carbon rap.” The deposits can also flake off and become trapped between the valves and valve seat, resulting in compression loss.

Higher compression and stored heat increase the likelihood of pre-ignition “knock” when the fuel spontaneously combusts prior to spark ignition. This increases emissions and may cause engine damage. Most vehicles have sensors that adjust spark timing to prevent knock. Although audible “knock” is controlled, power is lost from retarded timing and engine efficiency suffers. Higher octane fuels can be used to help prevent the phenomenon. As a vehicle ages, more-expensive, higher-octane fuel is needed to keep it operating at peak performance.

The Problem – Combustion chamber deposits:

• Increase the possibility of “carbon rap”

• Contribute to compression loss, difficult starting, and rough idling

• Increase the possibility of pre-ignition “knock” or “pinging”

The Solution:

AMSOIL P.i. fuel injector cleaner fights combustion chamber deposits which help restore power, control knock, increase fuel economy and reduce the need for higher-octane fuels.

Carbureted Engines

Although modern vehicle models are equipped with fuel injection systems, there are still a number of older and classic carbureted cars on the roads. P.i fuel injector cleaner works just as effectively in carburetors as it does in fuel injectors, intake valves, and combustion chambers, effectively cleaning the back sides of carburetor plates, the idle air passages, and all of the fuel portals just as well as it cleans the components of a fuel injection system.

Capless-Compatible Packaging

Many new vehicles have replaced traditional fuel caps with capless systems. The threads on most bottles restrict them from opening the flap inside the fuel neck and also make removing the bottle difficult. The P.i. fuel injector cleaner bottle is fully compatible with capless fuel systems

Benefits of P.i. Fuel Injector Cleaner Treatment

- AMSOIL P.i Fuel injector cleaner Increases fuel economy Testing yielded improvement of up to 5.7 percent

- AMSOIL P.i Fuel injector cleaner Restores power, acceleration and drivability to “like new” condition

- Reduces emissions and helps vehicles pass emission tests

- Up to 15 percent reduction in hydrocarbon (HC) emissions (unburned fuel)

- Up to 26 percent reduction in carbon monoxide (CO) emissions (partially burned fuel)

- Up to 17 percent reduction in nitrous oxide (NOx) emissions

- Fuel injector cleaner avoids necessity of expensive injector cleaning services

- AMSOIL P.i Fuel injector cleaner reduces engine octane requirement, saving money at the pump

- Excellent fuel injector cleaner for both gasoline direct injected (GDI) and port fuel injected engines

How to use AMSOIL P.i fuel injector cleaner

- Open fuel cap on vehicle

- Open AMSOIL P.i fuel injector cleaner bottle – remove cap seal

- Add entire bottle of P.i fuel injector cleaner to fuel tank at fill-up

- P.i fuel injector cleaner can treat one full tank of gas up to 30 gallons (113 Litres) with one bottle or up to 40 gallons (151 Litres) with two bottles. Using more than two bottles per treatment is not recommended.

- Large gas tanks should only be partially filled to 40 gallons (151 Litres) to maintain the proper concentration ratio of one fuel injector cleaner bottle per every 30 gallons (113 Litres) for best results.

- For best results, clean your fuel system with P.i. fuel injector cleaner every 4,000 miles (6,437 kilometres) (or 100 hours for marine, stationary and off-road gasoline-powered engines)

- Do not use AMSOIL P.i fuel injector cleaner with diesel or E85 fuel or two-stroke engines.

Why Fuel Injector Deposits Have A Significant Impact on Fuel Economy and Emissions

Port fuel injector deposits have a significant impact on fuel economy and emissions because they plug injectors at uneven rates, and the engine cannot compensate for individual cylinders. For example, a four-cylinder engine could have two plugged injectors, while the other two may only be mildly plugged or not plugged at all. The oxygen sensor indicates to the computer that the engine is not receiving enough fuel, so it increases the fuel supply to all four cylinders. Now the two injectors that were plugged are providing more fuel, but it still may not be enough, while the two injectors that weren’t plugged are providing more fuel than necessary. As a result, it creates a situation where two cylinders are running rich and the other two are running lean. Removing port fuel injector deposits allows the engine to operate as it was designed, improving fuel economy, lowering emissions, and contributing to improved drivability (reduced stumbling, stalling, hesitation, and rough idle) and increased power.

By measuring oxygen, the oxygen sensor in the exhaust stream is able to calculate how much gasoline the injectors are spraying, as well as the air/fuel ratio. Although vehicles are usually equipped with many fuel injectors (one per cylinder), only one oxygen sensor monitors them all. Through the oxygen sensor, the computer is able to determine if the engine is receiving the right amount of fuel. Deposit build-up on the injectors reduces the fuel flow. When the computer determines that the engine is not receiving enough fuel, it increases fuel flow from all the injectors in the fuel system. Although this solution would work well if all the injectors lost fuel flow at the same rate, injectors almost always plug at different rates based upon their operating temperatures (inboard cylinders typically run hotter) and individual manufacturing tolerances.